Internal structure: Geometrically defined but not repeating.

Goal: Parts with complex internal channels providing thermal optimization, mechanical or hydraulic functions, lubrication, i.e.

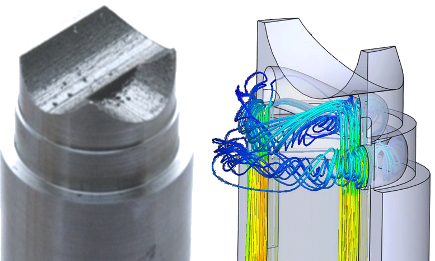

Tools with embedded cooling channels:

Left: Tool with embedded cooling channels produced by RM. Right: Flow simulation.

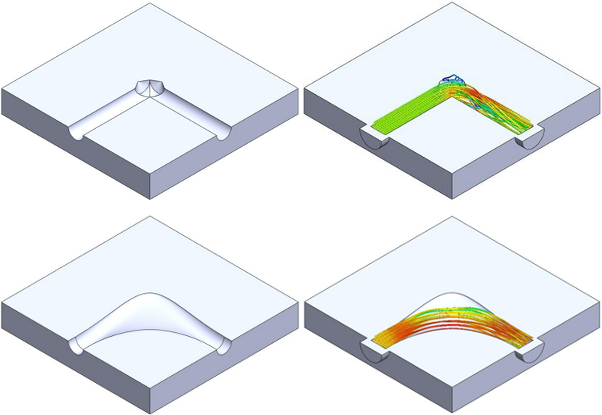

Hydraulic parts with improved flow:

The shaping, and hence the performance, of hydraulic parts are often limited by the use of traditional tools and a natural conservative thinking by the designer. As an example, consider this simple task: Construct a 90º bend channel within a metal block!

Traditionally, one would straightforwardly drill two channels which meet somewhere within the block. This method is fast, cheap and requires only traditional tools. However, the flow properties near the corner are seriously degraded by the geometry. AM, on the other hand, provide the designer with the geometric freedom to actually optimize the part with respect to its purpose. In this case, a low pressure loss is advantegeous, and guided by flow simulations, the optimal shape of the channel can be produced directly. For a real-world example, take a look at our case story: (Im)possible crossing.