Selective Laser Melting (SLM) is a layer-based rapid manufacturing process whereby a 3D CAD file is transformed into a finished metal part. The part is build by laser welding metal powder, one layer at a time, until the part is done.

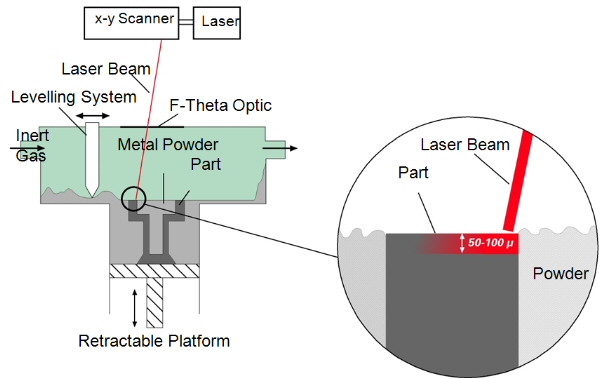

A sketch of the process is shown on the figure. The powder layers are laid out by a moving powder container, that deposit powder through the bottom. A plane surface is ensured by a wiper on the front of the container. The first layer is welded on a dense substrate which is mounted on a movable building platform. The successive layers are build by moving the platform one layer-thickness downward followed by new powder deposition. Movable mirrors scan the laser beam across the each layer. To control the amount of energy delivered to the powder, an f-theta lens keeps the beam focus right on the powder surface. Corrosion during the building process is avoided by filling the building chamber with an inert gas. As a lot of complex thermal stresses are developed in the part during building, the part is fastened to the substrate by some scaffold-like structures called support. The support is build together with the part itself.

The outcome of the process is influenced by a wealth of parameters. Examples are laser power, distance between the scanned tracks, size and geometry of the powder grains, the ambient temperature and the chosen support. Some parameters are more crucial than others but all have some influence on whether the part comes out as intended or not. One of the major challenges of the SLM process, is to find the right combination of parameters for a given part.